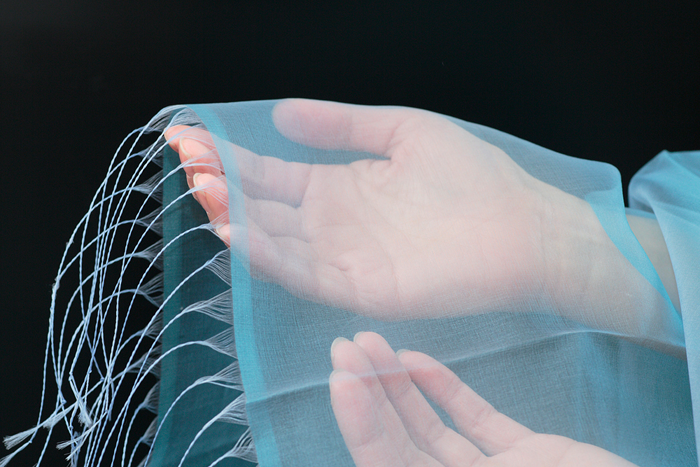

The fabric, so ethereal, makes us imagine the texture of the robes worn by the heavenly nymphs in Japanese folk tales. We named it Fairy Feather: the thinnest yarn-dyed silk fabric ever. It is made of ultra-fine silk threads with a thinness of 8 denier in diameter, equaling to 1/6 of the diameter of a hair (50 denier).

Thousands of ultra-fine silk threads are woven into the warps on looms to produce this exquisite organdy (ultra-light plain-weave fabric with transparency); it is weightless, yet the softness of the raw silk gently, and surely, cocoons the skin.

Fairy Feather

Winner of the Monozukuri Nippon Grand Award and the Good Design Award

Fairy Feather is the world' thinnest silk fabric—and not only that: we have succeeded to make it mass-producible by mechanical processes. These achievements gained a high evaluation, leading to our receipt of two prizes in 2012: the Prime Minister's Prize of the Monozukuri Nippon Grand Awards and the Good Design Award. At the time the Japanese textile industry was losing ground to foreign products, the Fairy Feather drew much attention as a product with competitive quality in the global market.

The Monozukuri Nippon Grand Awards

The the Good Design Award

Four years of development to reach commercialization

Between the research and the sale, it took four years of continuous development of this one-of-a-kind silk product. Even the cocoons that we use as raw material are special ones. Ordinarily, the cocoons to be used are the ones produced through four molts of silkworms; however, those used for Fairy Feather are made only through three molts and thus the fibers are finer and supple as spider's thread.

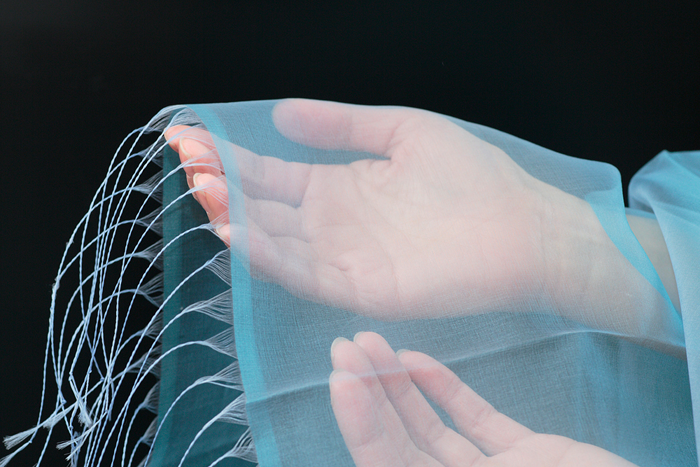

The reason we ventured to use ultra-fine silk threads—something other companies hesitate over—is because, above all, fine, light fabrics have been very popular in the fashion world. Yet, the leading wedding dress designer Yumi Katsura, our business associate since 30 years, also gave us an important clue with these words: "I would like to make lightweight wedding dresses so that brides can dance lightly in comfort."

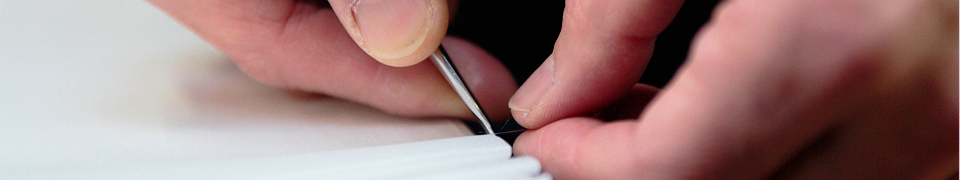

We have continuously made various improvements on the looms, in order to make the fabric not only mass-producible by mechanical processes, but also non-breakable and fuzz-free in heavy weaving movements of the loom, even when using the ultra-fine yarns made form the three-molt silkworms. By strictly controlling the tension of the threads, we finally managed to make the fabric into a commercial product: the Fairy Feather was thus born.

A wedding dress by Yumi Katsura